MEC Engineering Services is a provider of mechanical engineering services in various domain segments such as Aerospace, Automotive, Rail, Heavy Vehicle Engineering, Material procurement, Manufacturing etc.

Our major engineering services include:

- Product Design

- Finite Element Analysis

- Fatigue and Endurance life calculation

- Engineering support services

- Simulation and Prototyping

- Product Development

- Material Procurement

- Manufacturing support – Components, Assemblies & Sub Assemblies.

Design Engineering Services at MEC Engineering Services aspire to meet industry needs and challenges with precision engineering and program management skills.

From detail design of automotive, train, mechanical and aerospace components to large airframe and structures, MEC Engineering Services Engineering has the expertise in all the aspects of product engineering to meet the end customer requirements.

MEC Engineering Services Engineering maintains most compatible and experienced engineering staff with expertise in both commercial and aerospace programs, improving project implementation time while reducing costs. Added capabilities such as distance engineering with data transmission between the client and MEC engineering using secured data lines and internet technologies improves communication between the engineer and the user.

With the ability to understand customer needs MEC Engineering offers an environment that meets end user requirements.

- Product Design Solutions

- Drafting as per International standards such as BSI

- CAD model creation and validation

- Stress and Strain Analysis using latest FEA techniques

- Weight vs Cost studies

- Fatigue and Endurance Analysis

- CAD data conversion

- Software tool migration services

- Analysis of product

- Reverse Engineering

- Technical Publications

- Development Testing

- Qualification Testing as per International standards

- Jigs and Fixture Design

- Test rigs/ Test cells

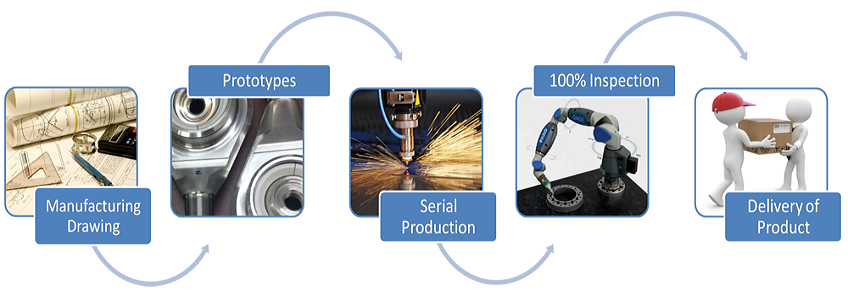

Manufacturing SERVICES

MEC Engineering is capable of providing manufacturing solutions as per customer requirements.

Manufacturing support is available for required customers and engineering resource is allocated wherever required to enable one to one service.

MEC Engineering has capabilities to cater for customer needs such as components, assemblies and sub assemblies.

- NC Programming

- Castings, Forgings and Machined parts

- Composites and Fabricated parts

- Machine Tool Modelling

- Production System Simulation

- Jigs and Fixtures

- Tool and Die design